How Membrane Switches Are Used to Improve Safety and Functionality in Machinery

How Membrane Switches Are Used to Improve Safety and Functionality in Machinery

Blog Article

Discovering the Perks of Membrane Switches for Modern Electronics

The exploration of membrane layer switches in modern digital devices offers a remarkable perspective on their myriad benefits, specifically in terms of design flexibility, resilience, and cost-effectiveness. As markets continue to evolve, the function of membrane layer buttons in boosting user experience and functional efficiency warrants better evaluation.

Advantages of Membrane Layer Switches

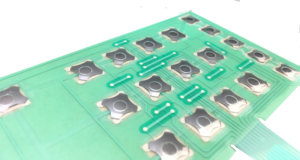

Membrane layer switches are progressively preferred in modern-day electronic devices as a result of their various advantages. Among the primary advantages is their compact style, which allows for space-efficient integration right into numerous tools. This slim account not just conserves area however likewise adds to the total aesthetic appeal of electronic items.

An additional benefit is their resilience. Membrane switches are typically resistant to wetness, dirt, and impurities, making them optimal for use in atmospheres where direct exposure to harsh conditions is a problem. This resistance prolongs the life expectancy of the buttons, minimizing the requirement for regular replacements and upkeep.

Furthermore, membrane layer switches over deal outstanding tactile responses, boosting individual experience. The tactile reaction is typically designed to offer a gratifying experience upon activation, which can enhance customer contentment and performance.

In addition, the manufacturing procedure of membrane layer switches is economical, allowing for reduced manufacturing expenses contrasted to typical mechanical buttons. This cost makes them ideal for a variety of applications, from customer electronic devices to industrial equipment.

Design Versatility and Customization

The design versatility and personalization options offered by membrane changes better enhance their charm in contemporary electronics. These buttons can be tailored to meet details visual and functional demands, enabling manufacturers to produce tools that straighten closely with brand name identification and user preferences. With numerous alternatives in terms of shades, forms, and dimensions, membrane buttons can seamlessly incorporate into diverse product layouts, whether for consumer electronic devices, industrial applications, or medical devices.

In addition, the capacity to incorporate graphics and icons directly onto the button surface enhances use while reducing the need for additional labeling. This assimilation not only simplifies production processes however likewise adds to a sleeker overall appearance. The style can be more personalized with features such as backlighting, responsive comments, and multi-layer constructions, offering boosted user interaction.

Sturdiness and Environmental Resistance

Furthermore, membrane layer switches can be engineered why not try these out to be chemically immune, making them appropriate for applications in commercial atmospheres where direct exposure to solvents and cleaning representatives is usual. The encapsulation of electronic components within the membrane structure gives extra defense versus ecological stress and anxieties, making certain reliable performance also in challenging conditions.

Along with physical sturdiness, membrane changes display outstanding resistance to UV light, avoiding destruction and staining with time (membrane switch). This characteristic is particularly beneficial for exterior applications, where long term exposure to sunshine can endanger various other switch types

Ultimately, the sturdiness and environmental resistance of membrane layer switches over make them an ideal option for a variety of modern-day electronic gadgets, from medical tools to consumer electronics, making sure regular functionality and customer satisfaction across numerous applications.

Cost-Effectiveness in Manufacturing

Cost-effectiveness in production is a significant advantage of membrane buttons, making them a favored selection for suppliers in numerous industries. The manufacturing process of membrane layer switches over usually involves fewer products contrasted to typical switches, which decreases raw product prices. This structured production process not just conserves money however also reduces waste, lining up with contemporary sustainability goals.

Furthermore, membrane layer buttons can be produced utilizing automated techniques, enabling high-volume result with minimized labor prices. The combination of sophisticated printing technologies further enhances performance, making it possible for suppliers to achieve elaborate designs and functionalities without incurring substantial added costs. This scalability makes sure that production can adapt to altering market needs without endangering top quality or enhancing prices.

In addition, the lightweight nature of membrane switches over adds to set you back savings in shipping and handling, along with in the total style of electronic tools. By removing large parts, makers can optimize the overall product style, thus boosting market competitiveness. Generally, the cost-effectiveness of membrane changes not just advantages manufacturers financially yet likewise promotes innovation and quick product growth in the vibrant landscape of contemporary electronic devices.

Applications in Different Industries

Adaptability stands apart as a characteristic of membrane buttons, allowing them to find applications across a variety of markets. In the healthcare industry, these switches are important to clinical tools, giving straightforward interfaces for tools like infusion pumps and diagnostic devices. Their resistance to moisture and simple cleansing make them ideal for settings calling for stringent hygiene standards.

In the vehicle sector, membrane buttons contribute to the performance of control panels and control panels, offering a smooth, contemporary look while making sure durability against rough problems. Their light-weight layout likewise sustains overall lorry effectiveness.

Furthermore, commercial machinery utilizes membrane layer switches for operational controls. Their robust nature and customizable features satisfy the specific needs of diverse applications.

Verdict

In conclusion, membrane layer switches offer substantial advantages for modern electronic devices, including design adaptability, longevity, and cost-effectiveness. membrane switch. Their adjustable features and resistance to ecological variables make them appropriate for a vast array of applications throughout different markets. As technological demands proceed to develop, the adaptability and effectiveness of membrane changes placement them as an important part in enhancing customer experience and driving development within the competitive landscape of digital tools

Report this page